Introduction

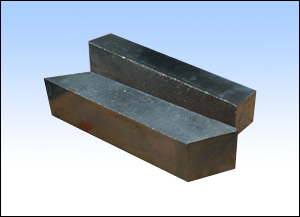

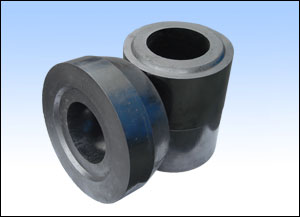

Long Yi brand Bricks is based on the use of different parts of the kiln and the use of different conditions designed and manufactured using high purity, high density, or large crystal magnesia and high purity graphite and resin raw materials, production of high-pressure molding process .

The product is widely used in the furnace lining, converter lining, refining ladle slag line and other parts, but can choose every part of the lining of different brands of Bricks, high strength, strong resistance to slag, thermal shock stability, fire high and so on.

Main physical and chemical indexes of MgO- C Bricks

Items | Index | |||||||||

MT10A | MT10B | MT10C | MT14A | MT14B | MT14C | MT18A | MT18B | MT18C | ||

Chemical ingredients(%);≥ | MgO | 80 | 78 | 76 | 76 | 74 | 74 | 72 | 70 | 70 |

C | 10 | 10 | 10 | 14 | 14 | 14 | 18 | 18 | 18 | |

Macro porosity rate(%);≤ | 4 | 5 | 6 | 4 | 5 | 6 | 3 | 4 | 5 | |

Volume density(g/cm3 );≥ | 2.90 | 2.85 | 2.80 | 2.90 | 2.82 | 2.77 | 2.90 | 2.82 | 2.77 | |

Compressive strength(Mpa);≥ | 40 | 35 | 30 | 40 | 35 | 25 | 40 | 35 | 25 | |

High temperature folding strength(1400°C×0.5h)(MPa); ≥ | 6 | 5 | 4 | 12 | 8 | 5 | 10 | 7 | 4 | |

Trade Standard of Magnesia Carbon Brick

(YB/T4074-1991)

Items | Index | ||

MT14A | MT14B | MT14C | |

MgO,%≥ | 76 | 74 | 74 |

C,%≥ | 14 | 14 | 14 |

Macro porosity rate,%≤ | 4 | 5 | 6 |

Volume density,g/cm3≥ | 3.0 | 2.82 | 2.77 |

normal temperature compressive strength,Mpa≥ | 40 | 35 | 25 |

high temperature anti-breaking strength,Mpa (1400°C×30min)≥ | 12 | 8 | 5 |